1. Polishing using ELEPURE™ Catalyst

During this stage, used or dark base oil is passed through the system under precisely controlled pressure, flow rate, and temperature, customized based on the specific oil characteristics. These parameters are critical to achieving optimal polishing results.

The system is equipped with a fully automatic control panel, which ensures accurate regulation of these variables—eliminating the need for constant human supervision.

By perfect regulation, the system delivers exceptional quality base oil output, improving oil color, reducing sulfur content, and enhancing oxidation stability, removing bad smell.

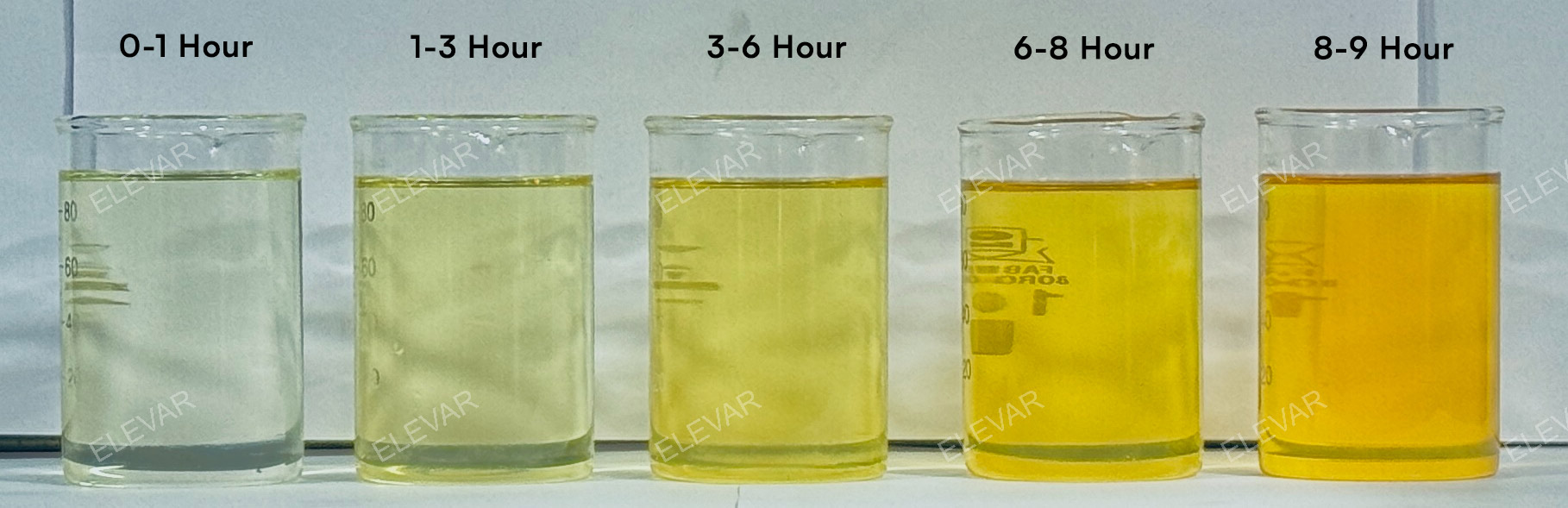

Output Colors of Distilled Dark Base Oil AFter Polishing Over 8 Hour Polishing Cycle

Insight of timeline…

A. Dark base oil or petroleum product is fed into the Oil Polishing System.

B. The feed travels through specialized columns under precisely controlled conditions- pressure, flow rate, and temperature-which are customized based on the characteristics of the feed material.

C. Depending on the feed’s properties, it takes approximately 5 to 7 hours before the first polished material begins to appear.

D. The initial output is typically clear and water-white in color.

E. Over time, the output color gradually shifts to a yellowish or orange shade.

F. This output continues for approximately 8 to 16 hours, depending on the nature of the feed.

G. During this period, the average color of the material in the final output collection tank is observed. Once the output reaches the maximum acceptable color limit, feeding must be stopped.

H. At this point, the media inside the columns is considered saturated and must undergo regeneration to prepare it for the next polishing cycle.

2. Regeneration of ELEPURE™ Catalyst

After the polishing cycle is complete, the ELEPURE™ catalyst must be regenerated to prepare it for the next cycle.

This is done through a thermal oxidation cleaning process, which removes accumulated contaminants from the catalyst surface.

The regeneration process is also fully automated, managed by the system’s built-in automatic controls to ensure proper regeneration of catalyst.

Using this system, Elevar Engineering Pvt. Ltd guarantees minimum 150+ regeneration cycles — while maintaining its polishing efficiency.